How Do Thin Position Sensors Work?

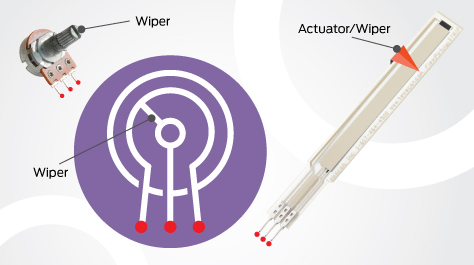

Figure 1: Thin position sensors, such as the strip sensor shown on the right, share many of the same functional characteristics of an electrical potentiometer (left).Thin linear potentiometers, or position sensors, are a unique component used to correlate the specific position of an actuator, physical contact, or touch to the sensor’s output. When physical contact is applied to the conductive area, the electrical output of the sensor varies with respect to the position of the actuator.

Figure 1: Thin position sensors, such as the strip sensor shown on the right, share many of the same functional characteristics of an electrical potentiometer (left).Thin linear potentiometers, or position sensors, are a unique component used to correlate the specific position of an actuator, physical contact, or touch to the sensor’s output. When physical contact is applied to the conductive area, the electrical output of the sensor varies with respect to the position of the actuator.

Thin position sensors consist of conductive material that is laminated between two flexible substrates. When completed, the sensor itself has a thickness of just 0.208 mm (0.008 in.).

Thin position sensors function very much like an electrical potentiometer, as demonstrated in Figure 1. Electrical potentiometers produce a variable resistance output that varies according to the position of a wiper. The functionality of a position sensor is the same, with the actuator on the sensor’s active region acting like a wiper of an electrical potentiometer.

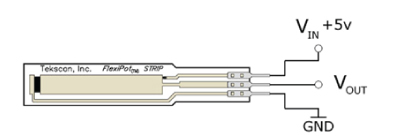

As shown in Figure 2, by applying a fixed voltage (VIN) across the outer pins, the middle pin of a flexible position sensor measures the voltage output (VOUT). With this circuit, the voltage output reading will be linear (±2%) with respect to change in position.

If two separate locations are loaded on this sensor, the voltage output will be that of the contact made closest to the grounded pin (GND).

At Tekscan, we refer to our thin position sensors as FlexiPot™ sensors.

Figure 2: Recommended circuit for a FlexiPot thin position sensor.

Figure 2: Recommended circuit for a FlexiPot thin position sensor.

How Durable Are Thin Position Sensors?

While this article does not speak for all thin position sensor technologies, according to third-party durability data1, FlexiPot sensors were able to withstand 1.5 million actuator swipes, and maintain their typical performance, with no signs of degradation. Also, in FlexiForce™ sensor durability tests– which are composed of the same substrates as a FlexiPot sensor – the sensors were shown to withstand upwards of six million force actuations, with no discernable change in sensor performance.

Given these durability trials, we can be assured that FlexiPot sensors will withstand the rigors of most any position-sensing application.

Other performance specifications include:

- Repeatability: <±1% of full scale

- Spatial Resolution: <2% of full scale

- Operating Temperature: Standard: -40°C - 60°C (-40°F - 140°F); High-Temp: -40°C - 204°C (-40°F - 400°F)

What Actuator Materials (e.g., Wipers) Are Recommended for Thin Position Sensors?

Any smooth, low-friction material can become a sufficient actuator for a flexible position sensor. Some of the more common options include:

- Delrin

- Metal (as long as there is no hard edge)

- Poly-carbonate

- And, human skin

Generally, the size of the actuator contact area should be as large as possible to cover up to 60% of the width of the sensor’s active area. Also, it is recommended, out of precaution, to design the actuator to apply only as much contact pressure as necessary, in order to prolong the sensor life. The recommended contact pressure is between 34.5 – 345 kPa (5 – 50 PSI).

What Type of Electrical Circuitry is Recommended for Thin Position Sensors?

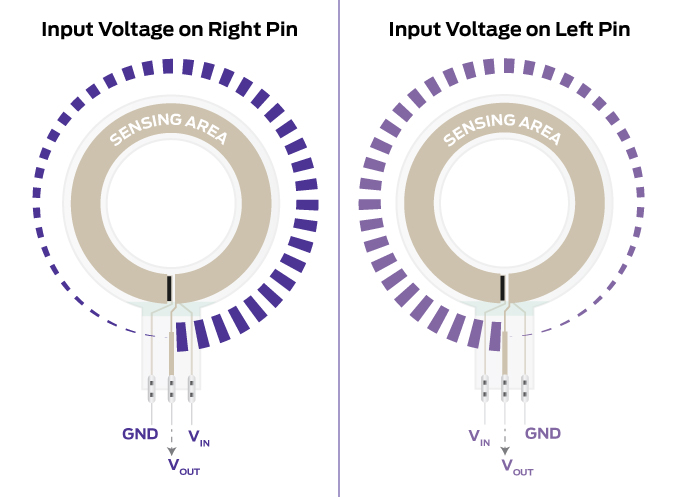

As stated earlier in this article, the only electrical requirement needed to power a linear potentiometer, or thin, flexible position sensor, – no external circuitry is required. However, one important consideration to note is that the position-output functionality of a flexible position sensor is dependent upon what end of the sensor is receiving the input voltage (VIN).

Figure 3: The position reading is dependent upon where the input voltage is fed into the FlexiPot's sensor connection.As shown in Figure 3, by applying the input voltage (VIN) to the pin on the right side of the ring sensor, and the sensor grounded on the left pin, the position output will descend from the right to the left. Conversely, driving VIN on the left, and grounding on the right pin, the output would descend from left to right. FlexiPot sensors do not have a polarity.

Figure 3: The position reading is dependent upon where the input voltage is fed into the FlexiPot's sensor connection.As shown in Figure 3, by applying the input voltage (VIN) to the pin on the right side of the ring sensor, and the sensor grounded on the left pin, the position output will descend from the right to the left. Conversely, driving VIN on the left, and grounding on the right pin, the output would descend from left to right. FlexiPot sensors do not have a polarity.

Also, in the case of FlexiPot sensors, their shape, size, operating temperature, and electrical termination, can all be customized to fit the needs of a specific position-sensing application.

What Are Some Commonly-used Applications for Thin Position Sensors?

The thin, minimally-invasive nature of flexible position sensors make them an attractive option to capture and monitor position data, without adding excessive complexity to a design.

While new uses for these sensors are constantly being discovered, these are just a few broad examples flexible position sensors are being used in applications now.

|

|

|

|

|

|

Where Can I Purchase Thin Position Sensors?

Whether you’re working on a device prototype, or a position measurement application of some sort, FlexiPot sensors are available to purchase from Tekscan’s online store in low-cost, low-commitment 4-and 8-packs. FlexiPot sensors are available standard in both strip and ring format. This core technology can be customized to most any shape your design requires.

See FlexiPot Sensors in Action!

For more information about FlexiPot flexible position sensors,

(1) For more information on this independent study, please reach out to us at info@tekscan.com.