The One Thing New FlexiForce Users Need to Know

Ed Haidar - Tekscan Applications EngineerWe recently sat down with Tekscan Application Engineer Ed Haidar, and asked him if there was ONE thing FlexiForce™ users can do in their integration process to put them on the path to success.

Ed Haidar - Tekscan Applications EngineerWe recently sat down with Tekscan Application Engineer Ed Haidar, and asked him if there was ONE thing FlexiForce™ users can do in their integration process to put them on the path to success.

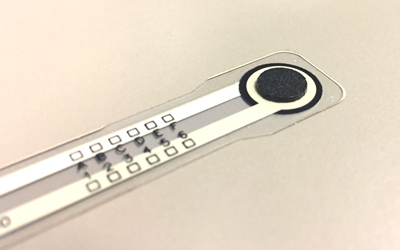

Ed's response?: When in doubt, use a puck. Example of a puck covering 70-85% of an A201 sensing area.

Example of a puck covering 70-85% of an A201 sensing area.

Why is a puck so important? Using a puck (AKA, a load concentrator) will help ensure that engineers are following the “100-70 Rule”—that is, best results will be achieved when 100% of the force is concentrated within the sensing area, and that 70-85% of the sensing area is loaded. The best way to accomplish this is through using a puck.

Testing should be performed with different materials to determine the best puck material for the application. Neporene, polycarbonate, delrin, aluminum, and stainless steel are a few viable options that have been used successfully on FlexiForce applications.

There are two key scenarios where using a puck can optimize the load performance of a FlexiForce.

|

|

In a Distributed Load scenario, the contact area is bigger than the sensing area, which can result in offloading. Using a puck can help ensure a more accurate measurement from cycle-to-cycle by concentrating the load force evenly onto the sensing area. |

|

|

In a Point Load scenario, the contact area is much smaller than the sensing area. Using a puck can help reduce the effect of excessive contact pressure on a specific part of the sensing area, which can prompt plastic deformation and compromise sensor repeatability. Also, pucks can also compensate for when the load actuator does not load in the same area of the sensor each time, thereby reducing variable output. |

So, now that you understand these key functions, here are three questions to ask yourself to determine if your application may benefit from using a puck in the design:

- What is the contact area of the actuator relative to the sensing area of the sensor? If it's much larger or smaller than the sensing area, using a puck will ensure optimal sensor performance.

- Is the actuator loading in the same area each time? If not, a puck is necessary.

- What is the best puck material for the application? Compliant and rigid interface materials can behave differently when it comes to linearity, hysteresis, sensor response, shear, and other factors. During the design phase, test different interface/puck materials to see what will provide the best results.

Looking for Pucks?Tekscan now offers peel-and-stick delrin load concentrators for purchase from our online store, available in two different diameters to fit many of our standard sensors. |

FlexiForce load concentrators are peel-and-stick pucks that fit the sensing region for most FlexiForce standard sensors. FlexiForce load concentrators are peel-and-stick pucks that fit the sensing region for most FlexiForce standard sensors. |

Looking for more guidance working with FlexiForce sensors? Click the banner below to download the free FlexiForce Integration Guides.