Pressure Mapping Technology

Measure interface pressure between two surfaces, utilizing a thin and flexible sensor. The resulting data and our analysis tools offer insights to enhance product design, manufacturing, quality, and research.

Have questions? Contact Us

Measure interface pressure between two surfaces, utilizing a thin and flexible sensor. The resulting data and our analysis tools offer insights to enhance product design, manufacturing, quality, and research.

Pressure mapping is a unique test & measurement technology and prime example of a wide-reaching R&D tool. Top tier companies have successfully used our systems to help solve application challenges, improve product design, and more.

|

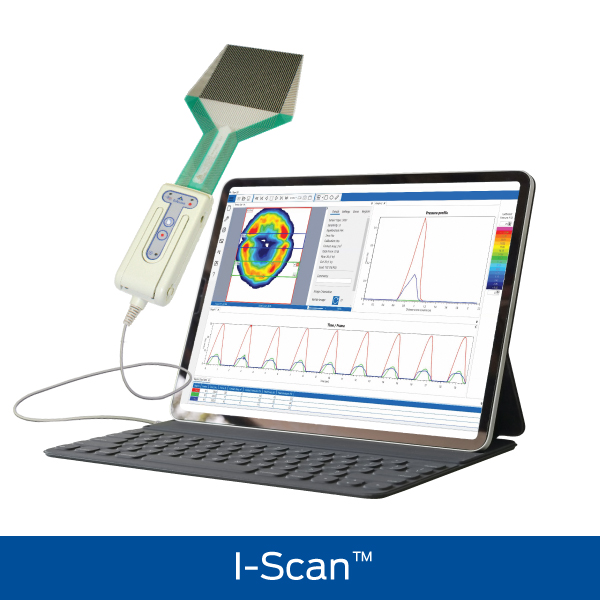

The I-Scan Pressure Mapping System The I-Scan Pressure Mapping System |

Measure and analyze interface pressure between nearly any two surfaces for many applications including energy storage and semiconductors to name a few. |

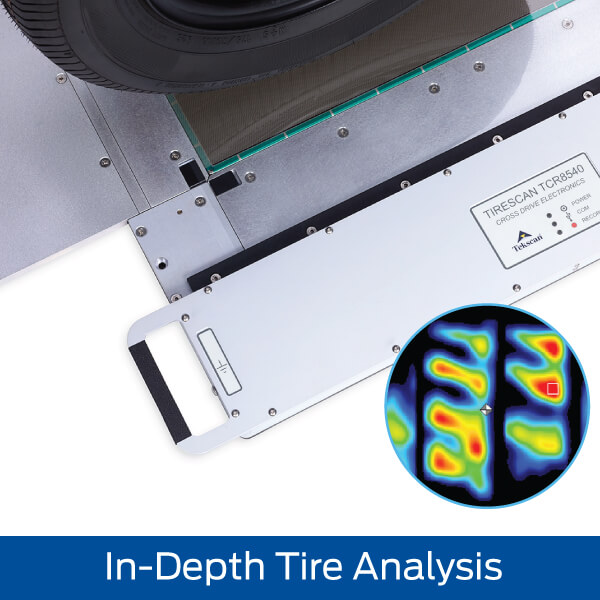

Improve tire designs, inside & out, with systems to analyze static or dynamic tire footprints, as well as tire bead seat & seal. |

Optimize designs for bedding, cushioning, positioning, and seating. |

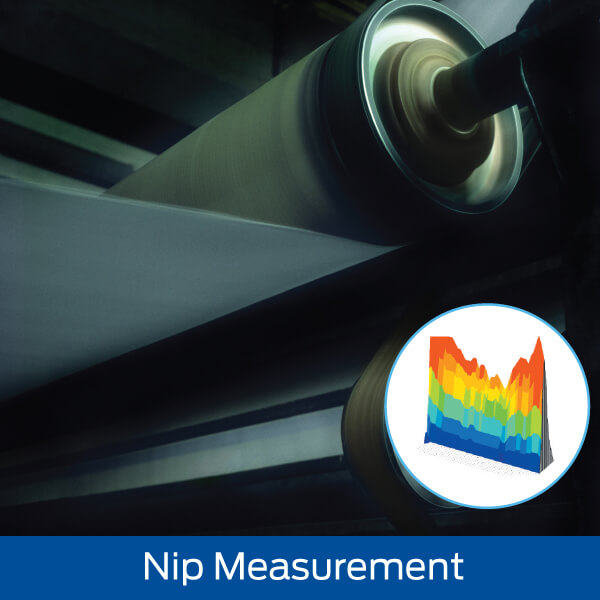

Verify nip roll uniformity and eliminate machine set-up guesswork. |

Quantify forces applied by the human hand while grasping objects. |

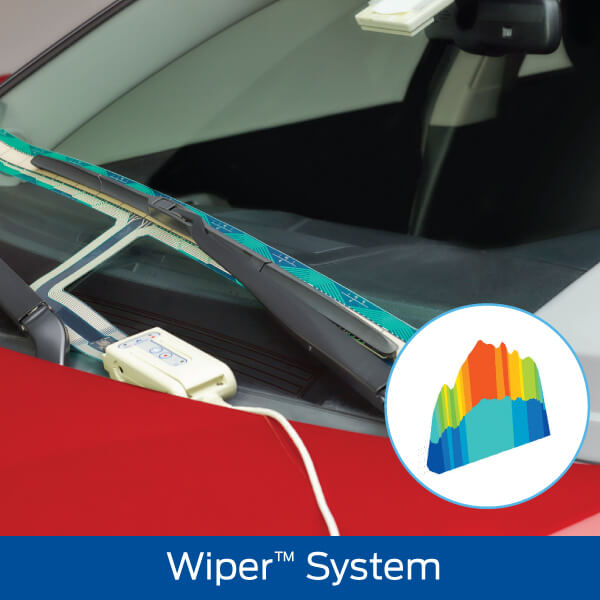

Evaluate wiper blade force profiles and interface pressure distribution. |

Sensors

|

Electronics

|

Software

|

Watch this five-part video series covering Pressure Mapping Technology's several uses to help enhance R&D processes:

|

Load Cells

|

Pressure Mapping Technology

|

Pressure Indicating Film

|

Pressure mapping technology has shown to be a proven tool to help R&D teams of all types capture actionable data that optimizes product development and opens new opportunities to improve manufacturing procedures.

Want to know how our pressure mapping sensors are made, and how they work? This short video provides a visual overview of Tekscan's pressure mapping sensor technology.

Learn the pros and cons of using pressure indicating film versus tactile pressure sensors.

This five-part video series covering Pressure Mapping Technology's several uses to help enhance R&D processes.