Taking the Bumpy Journey to Market

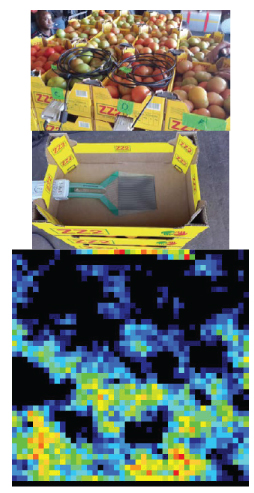

Figure 1: I-Scan pressure mapping sensors were placed within tomato crates to monitor item shifts during transit. The pressure map image shows one snapshot of pressure distribution on the way to market.

Figure 1: I-Scan pressure mapping sensors were placed within tomato crates to monitor item shifts during transit. The pressure map image shows one snapshot of pressure distribution on the way to market.

Challenge:

Food transportation can be especially difficult in underdeveloped nations, or regions with poor transportation infrastructure. Given their soft form factor, tomatoes are quite sensitive to excessive bumps on the road, which can lead to significant product losses on the way to their destination.

Solution:

A group of researchers in South Africa utilized pressure mapping technology in their studies to develop deterioration models that would predict the quality losses under different supply chain conditions. Sensors paired with accelerometers were placed within the tomato bins or cartons, as shown in Figure 1, to monitor impacts while traveling on some of South Africa’s more challenging roads.

Their results showed in-transit pressures did affect a tomato’s shelf life, and that packaging choice was also a critically important factor. Tomatoes transported in bins ripened faster and had structural damage as opposed to those transported in cartons (shown on the right).

The minimally-invasive nature of pressure mapping technology provides manufacturers with a better understanding of the shipping process, and allows them to make adjustments to their containment structures accordingly.

Similar applications:

- Smart packaging design

- Package tracking/theft management

- Delivery assurance

Source: University of Kwa-Zulu Natal (Department of Agricultural Engineering) in collaboration with the University of Pretoria (Department of Civil Engineering)

Choose Your Next Destination! Select From the Icons Below