Versatile Pressure Mapping System

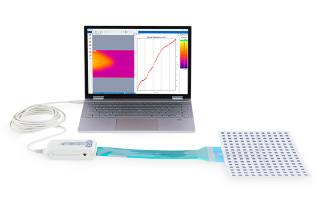

I-Scan™ is a powerful tool that accurately measures and analyzes interface pressure between two surfaces, utilizing a thin and flexible sensor. The system is comprised of data acquisition electronics, sensors, and software. Measuring both force and pressure, the exceptionally thin tactile sensor provides minimal interference between the objects being measured, allowing the true interface pressure data to be obtained. The interface pressure data collected offers vital information and insight to enhance product design, manufacturing, quality, and research.

Which I-Scan System is Best for Your Application?

I-Scan™ offers different options for data acquisition electronics. To help you choose the best fit for your application, explore the configurations below or download the I-Scan Product Selection Guide for more detailed information and specifications on the various system options, features, and configurations.

I-Scan Product Selection Guide

Browse Our I-Scan Configuration Options:

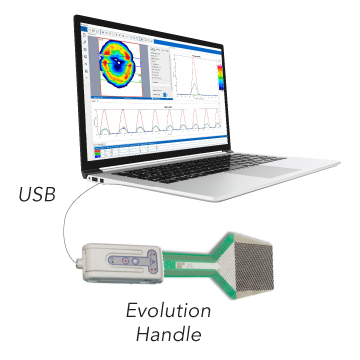

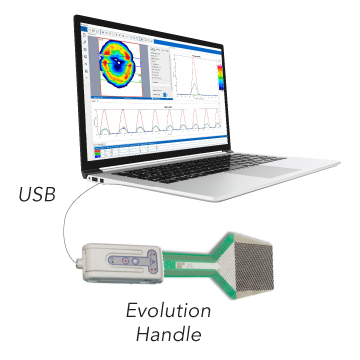

Evolution

For use in standard applications. Up to 100Hz scanning speed.

|

- Data Acquisition Electronics: Evolution™ Handle

- Maximum Scanning Speed: 100 Hz

- Cross Handle Scanning: No

- Pulse-per-Frame Synchronization: No

- Adjustable Sensitivity: x 3 to 1/7 of Sensor Pressure Rating

- Power Source: USB Port of PC

- Maximum Handle Cable Length: 5.0 m (16.4 ft.)

- Maximum Hub Cable Length: N/A

|

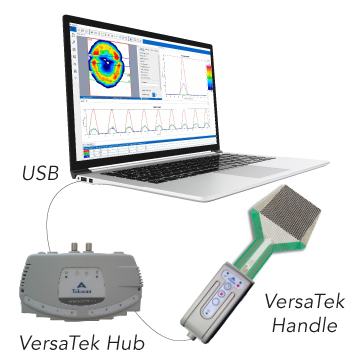

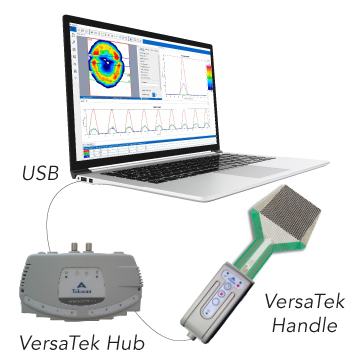

VersaTek

For use in high-speed applications (up to 20,000 Hz) or for sensors with higher resolution over large areas.

|

- Data Acquisition Electronics: VersaTek™ Handle with VersaTek Hub

- Maximum Scanning Speed: 20,000 Hz

- Cross Handle Scanning: Up to 8

- Pulse-per-Frame Synchronization: In & Out

- Adjustable Sensitivity: x 7 to 1/7 of Sensor Pressure Rating

- Power Source: 100-240V Power Supply

- Maximum Handle Cable Length: 30.48 m (100 ft.)

- Maximum Hub Cable Length: 5.0 m (16.4 ft.)

|

VersaTek Wireless

Note: VersaTek Wireless is a legacy wireless configuration that may only be used with I-Scan Version 7.

Wirelessly transmit data to PC for remote data collection (up to 100 m). Up to 4,600 Hz scanning speeds.

|

-

Data Acquisition Electronics: VersaTek Handle with Wireless Unit

-

Maximum Scanning Speed: 4,600 Hz

-

Cross Handle Scanning: Up to 2

-

Pulse-per-Frame Synchronization: In & Out

-

Adjustable Sensitivity: x 7 to 1/7 of Sensor Pressure Rating

-

Power Source: Li-Ion Battery: 8V, 2.4A or Power Supply: 100-240V

-

Maximum Handle Cable Length: 30.48 m (100 ft.)

-

Maximum Hub Cable Length: 5.0 m (16.4 ft.)

|

VersaTek Datalogger

Note: VersaTek Datalogger is a legacy wireless configuration that may only be used with I-Scan Version 7.

Collect data onto Datalogger Unit and upload to PC after data collection. For wireless use at higher speeds & noisy environments. Up to 20,000 Hz scanning speed.

|

- Data Acquisition Electronics: VersaTek Handle with Datalogger Unit

- Maximum Scanning Speed: 20,000 Hz

- Cross Handle Scanning: Up to 2

- Pulse-per-Frame Synchronization: In & Out

- Adjustable Sensitivity: x 7 to 1/7 of Sensor Pressure Rating

- Power Source: Li-Ion Battery: 8V, 2.4A or Power Supply: 100-240V

- Maximum Handle Cable Length: 30.48 m (100 ft.)

- Maximum Hub Cable Length: 5.0 m (16.4 ft.)

|

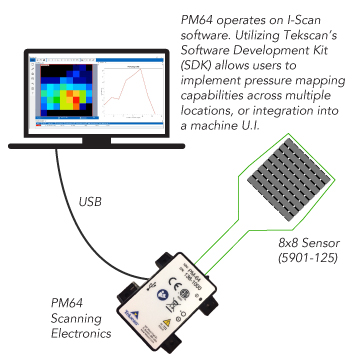

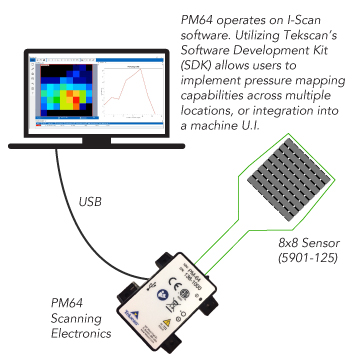

PM64

PM64™ is a basic pressure mapping scanning electronics module that supports a large-scale deployment for high-volume users and original equipment manufacturers (OEMs). When utilized with Tekscan’s software Application Programming Interfaces (APIs), PM64 provides a cost-effective, scalable solution as a live feedback loop for inline Quality Assurance/Quality Control testing, or as an embedded feature within a machine’s user interface (U.I.).

|

- Data Acquisition Electronics: PM64 electronics

- Maximum Scanning Speed: 100 Hz

- Cross Handle Scanning: No

- Pulse-per-Frame Synchronization: No

- Adjustable Sensitivity: x 3 to 1/7 of Sensor Pressure Rating

- Power Source: USB port of PC

- Maximum Handle Cable Length (Included): 0.9 m (3 ft.) Shielded USB 2.0 USB-A to RA USB Micro-B

- Maximum Hub Cable Length: N/A

|

Comparison Chart

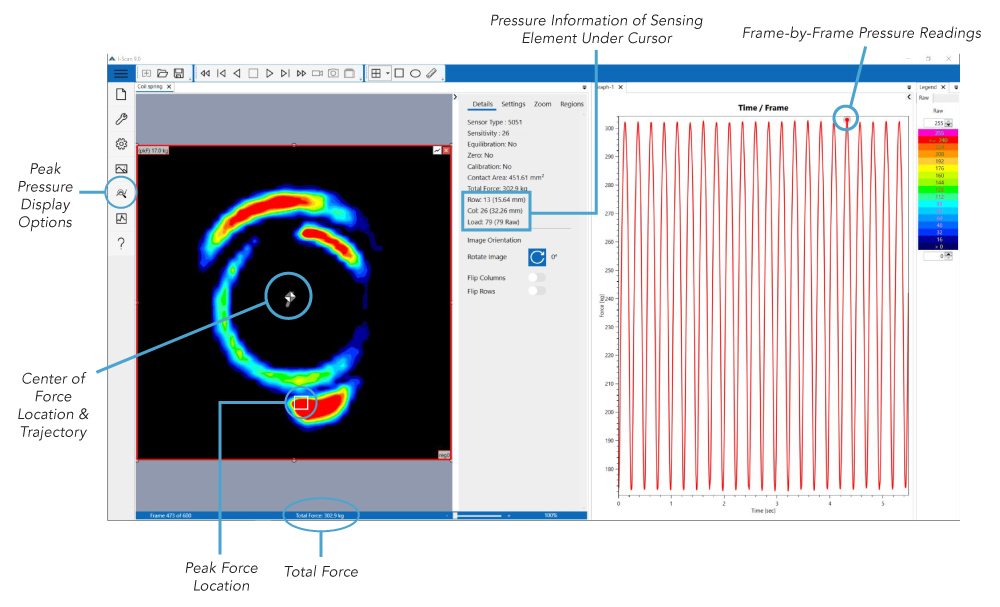

Superior Data Analysis

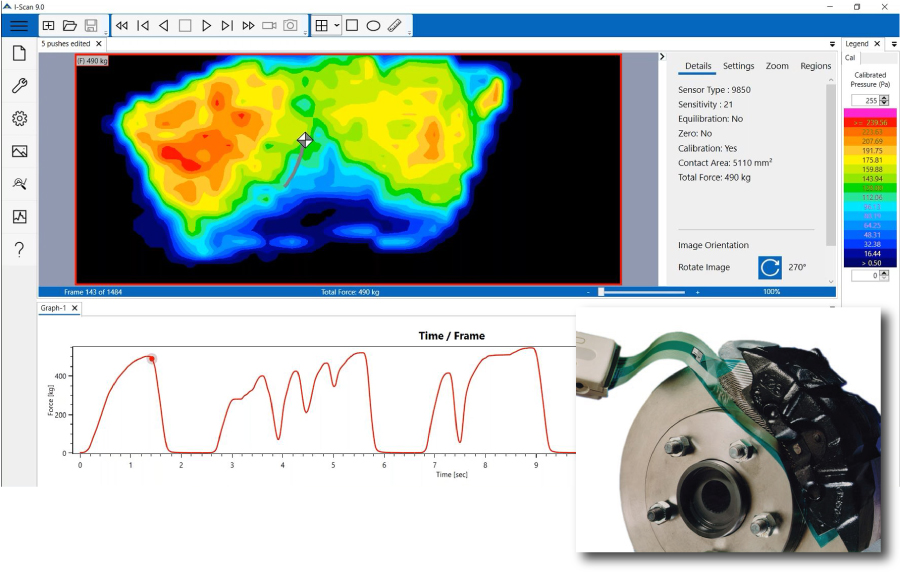

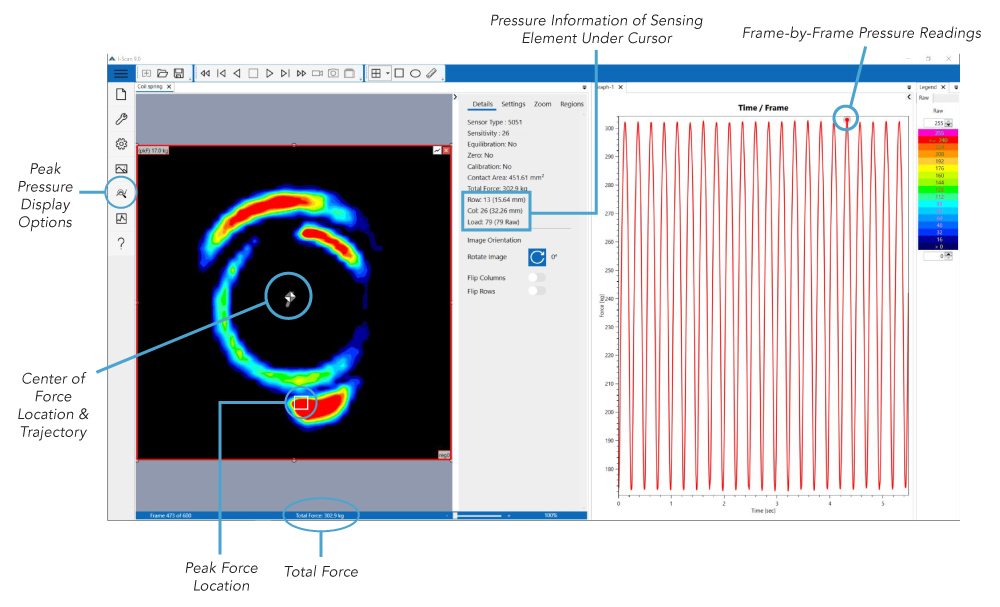

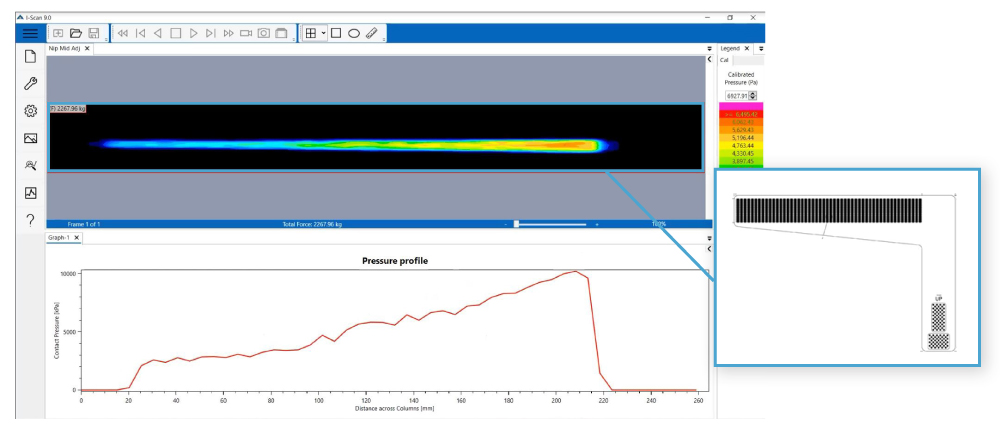

I-Scan™ provides the tools for more comprehensive and higher quality analysis than ordinary pressure sensing technologies.The software displays the pressure distribution data, in multiple formats, for superior analysis.

Key Features

- Real-time sensor data viewing

- Visualization enhancements of the pressure image

- 2D & 3D representations

- Interpolation, contours & averaging for clearer image

- Pressure displayed in engineering or relative units

- Single & multi-point calibration

- Analysis tools

- Center of force & trajectory

- Peak force and contact area identifiers

|

- ASCII export capability

- Save as AVI

- Sensor scan rate up to 20 kHz

- Graphical analysis of real-time or stored data

- Total force

- Contact area

- Contact pressure

- Peak force

- Peak contact pressure

|

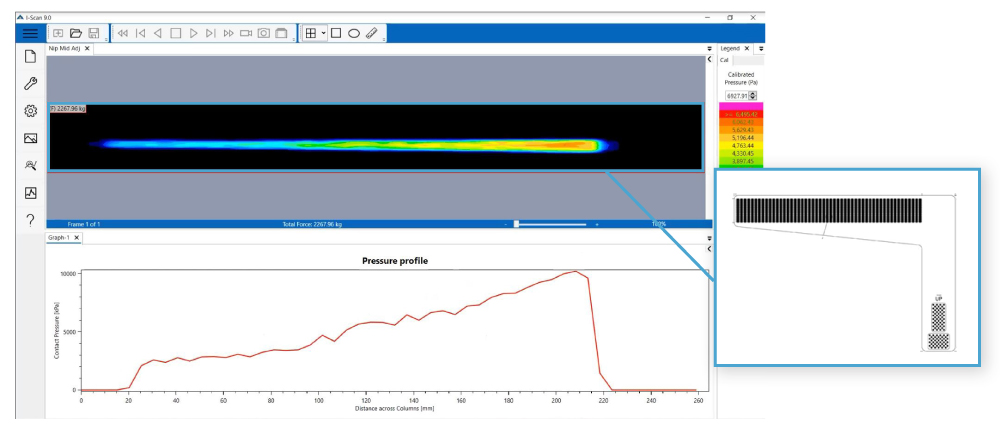

Graphic & Data Analysis

With the ability to capture force over time, users can click at any point of a pressure mapping recording to view the resulting pressure output image.

Data from each frame includes:

- Total force

- Center of force location

- Peak pressure

- Pressure distribution (e.g., force on each sensing element)

|

|

|

Each sensor requires its own unique MAP driver file for the software to function properly. By utilizing sensor MAPs, the software is able to provide an accurate depiction of each unique sensor layout. The sensor MAP controls the shape of the pressure image window in the software, which corresponds to the shape and dimensions of the sensing area on the sensor.

|

|

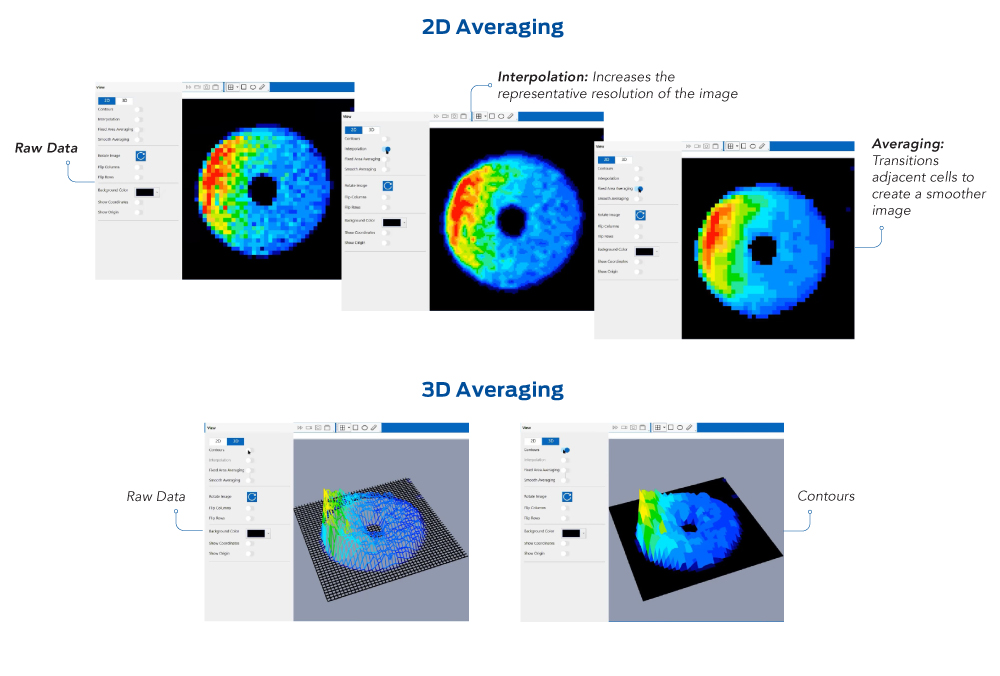

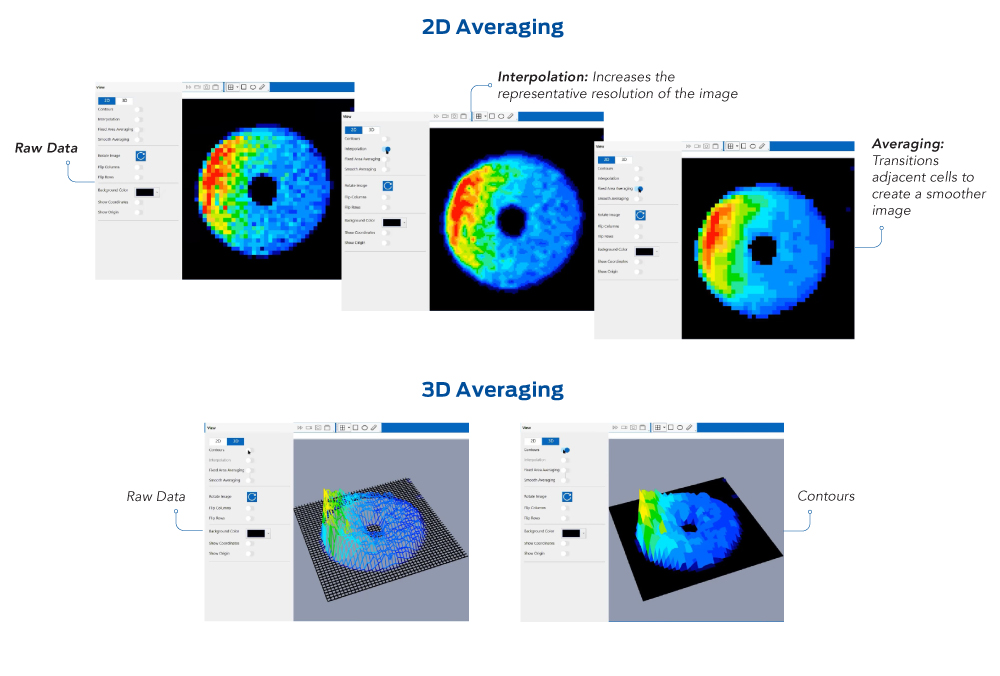

Visualization

I-Scan 9 offers optimized 2D and 3D display algorithms in the software to average sensor data into a smooth pressure map display; giving a more realistic representation of the object being measured.

Select among several averaging views, including combination views.

|

|

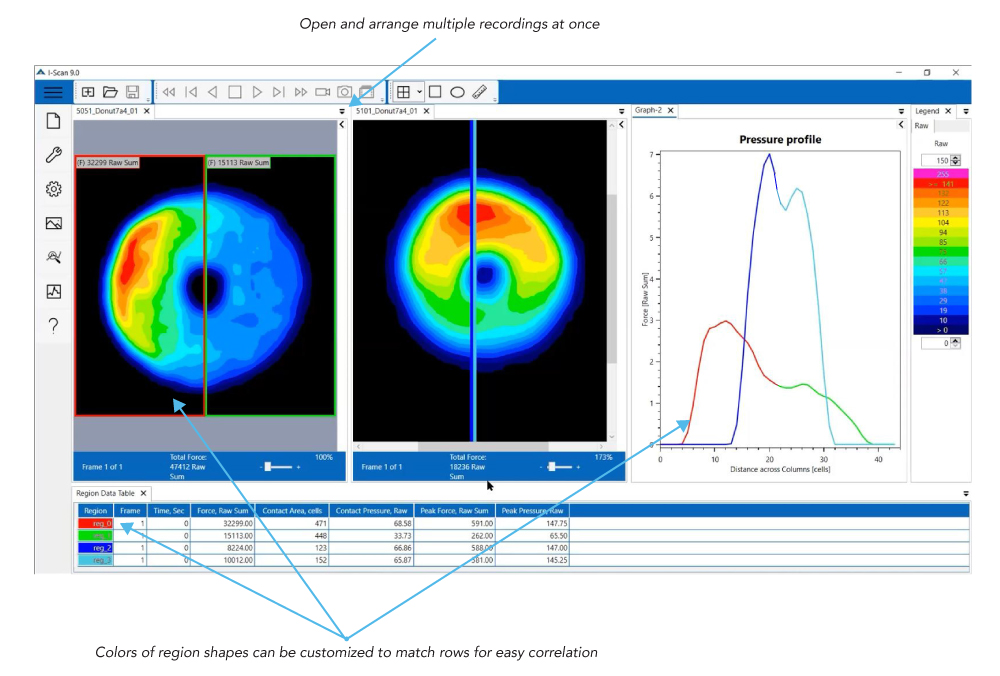

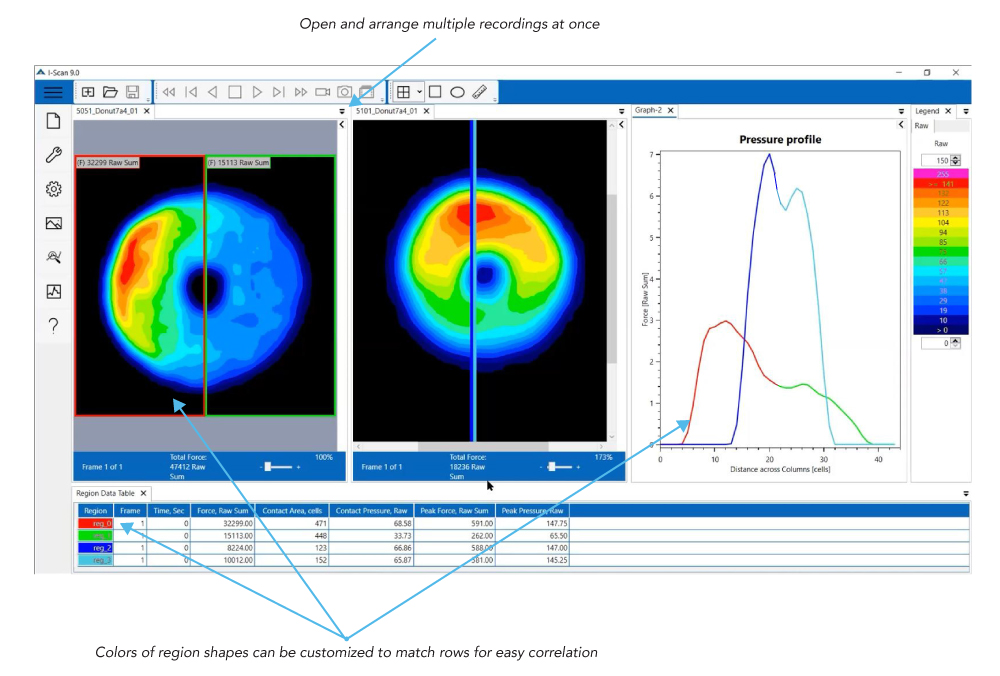

Property Table

I-Scan’s integrated property table displays key metrics of all regions placed on multiple data sets being analyzed simultaneously. Total Force, Contact Area, Contact Pressure, Peak Force and Peak Contact Pressure are displayed to allow for in depth comparison of multiple tests. Colors of region shapes can be customized to match names of rows for easy correlation.

|

|

View Computer Requirements

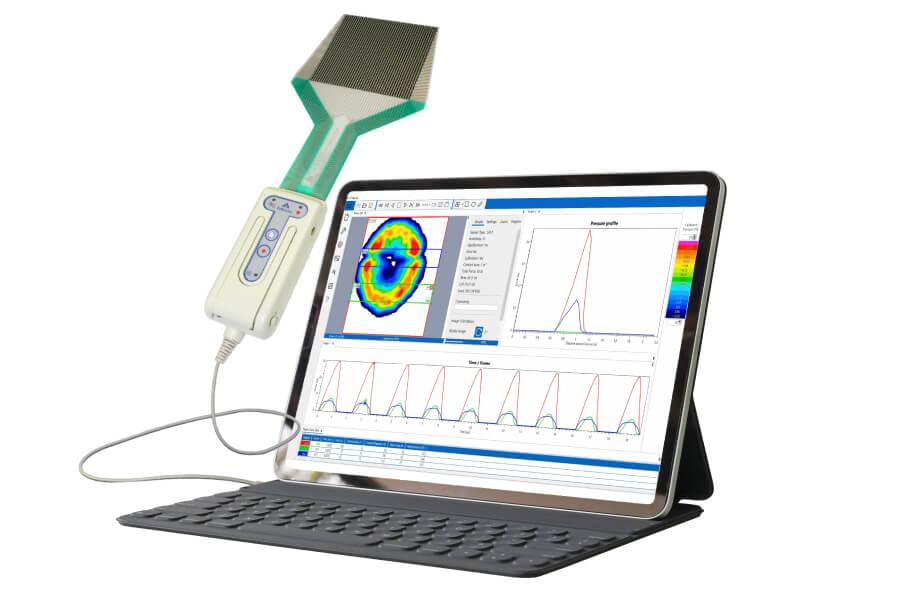

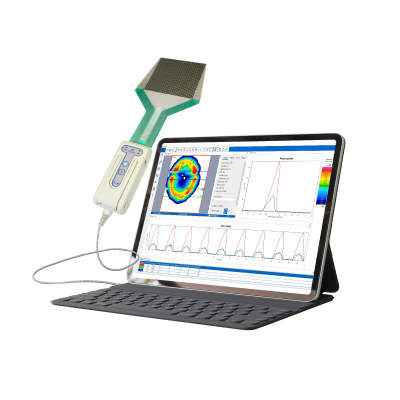

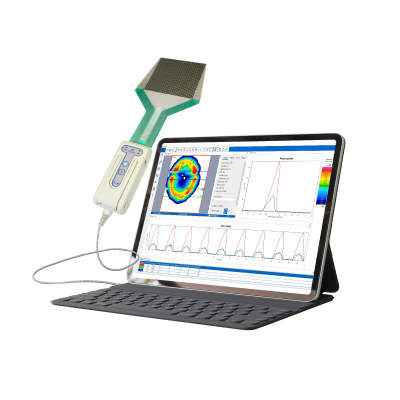

Tablet Compatibility

I-Scan Evolution software can run from a tablet operating on Windows 7 and up. This feature makes your I-Scan system more portable and provides other capabilities, including:

- Remote data collection and analysis

- Remote control of viewing recording/triggering of a system

- Ability to test in areas that may have safety risks, such as machine setup or production line spot checks

Requirements include:

- Tablet must have a USB A 2.0 connection

- Each tablet must have its own software license

- Only for use with one Evolution handle

- I-Scan software must be version 7 or above

Unique Applications for the I-Scan System

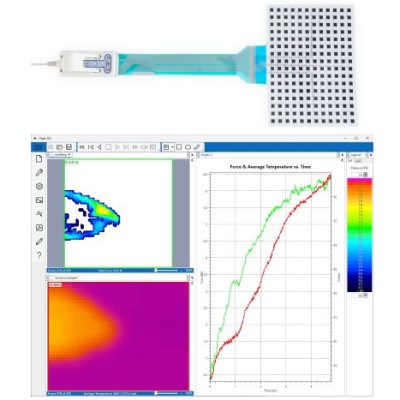

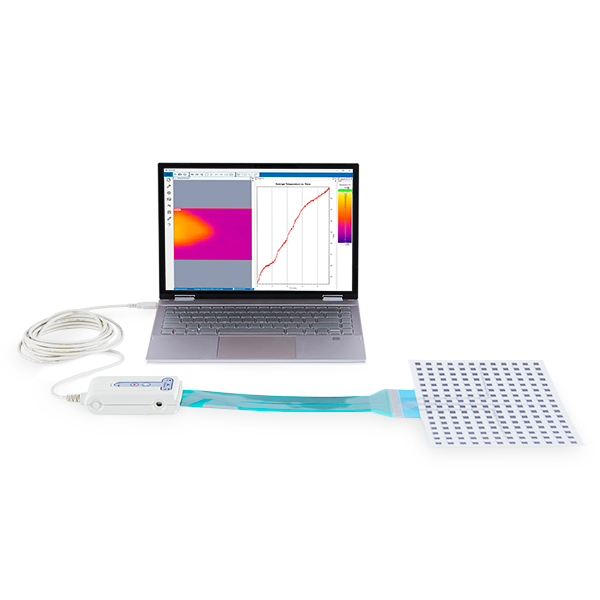

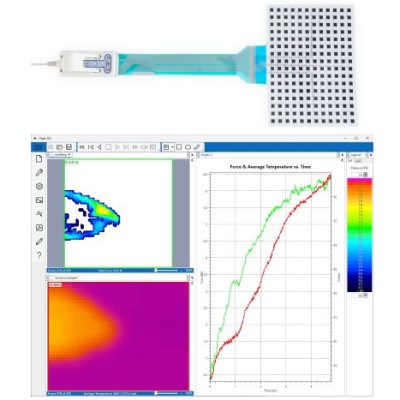

Temperature Mapping System

Temperature and Pressure Mapping Data Side by Side Temperature and Pressure Mapping Data Side by Side |

Add Temperature Mapping to your I-Scan Pressure Mapping System

Correlate Pressure & Temperature in one data set

By overlaying temperature mapping data with pressure mapping, the I-Scan reveals critical relationships between pressure and temperature affecting product performance and reliability.

You can see the real time data capture on the left, and the graph of changes over time in the software data display on the right.

|

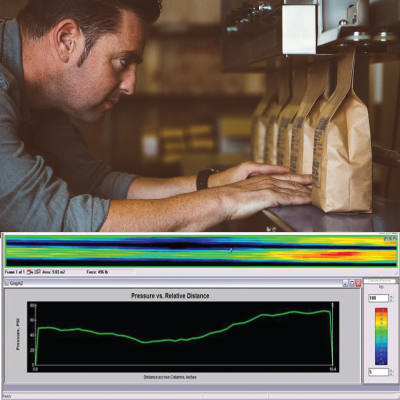

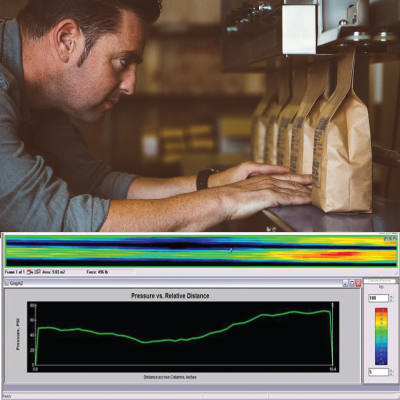

Food Packaging Sealing Bar

|

Challenge:

To establish baseline metrics for proper alignment of a high-temperature sealing bar machine.

- Eliminate risks of damaged product

- Ensure optimal quality for delivery to the consumer

Solution:

High-temperature I-Scan systems allows the operator to make routine adjustment to the maturing surfaces of the sealing bar.

- Assurance of a packaging seal that's free of defects, run-after-run

- Streamline machine setup process

- Better control of the production

|

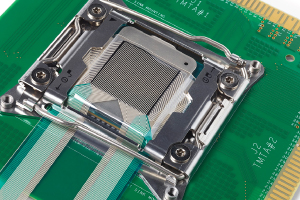

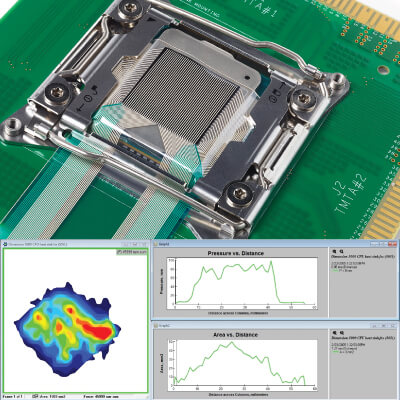

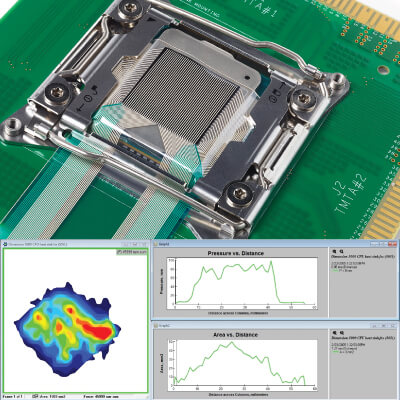

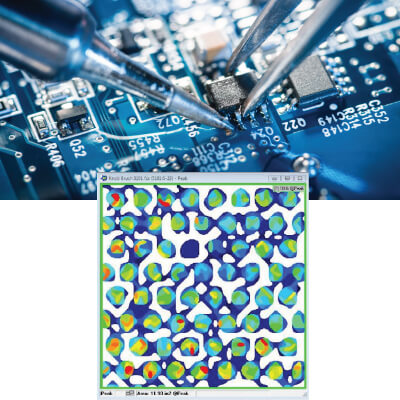

Heat Sink Contact Pressure

|

Challenge:

To measure and ensure contact pressure between a heat sink and heat source on a circuit board.

- Heat sinks are secured to components to dissipate heat from high-density, active electronics. Excessive heat can lead to system failure

- Even contact must be achieved between the part being cooled and the heat source

Solution:

The ultra-thin I-Scan sensor could be easily inserted between the two rigid mating surfaces to evaluate and improve contact.

- Used to identify potential contact gaps between the seemingly uniform surfaces

|

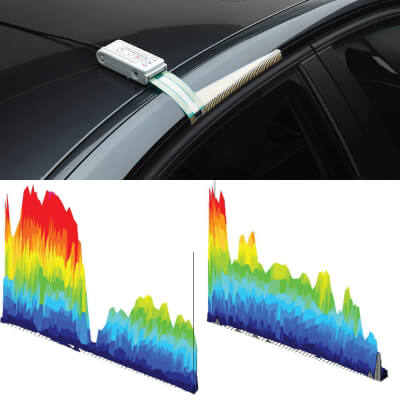

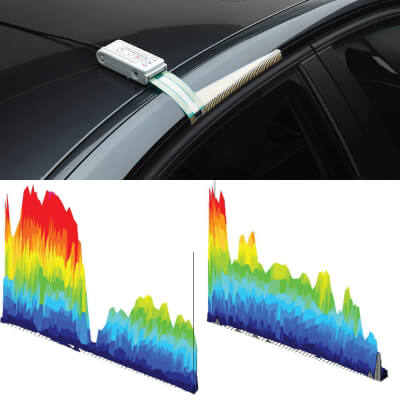

Automotive Door Seal Pressure

Image on the left shows pressure output before adjustments, while the right shows ideal pressure output after adjustments were made. Image on the left shows pressure output before adjustments, while the right shows ideal pressure output after adjustments were made. |

Challenge:

To analyze the contact pressure between a door and the rubber seal on a vehicle.

- Ensure proper adjustment of hinges and door latches while the vehicle is being assembled

- Vehicle assembly technicians will typically have to guess where to position door hinges and latches

Solution:

The I-Scan system functions as an electronic "feeler" gauge to measure contact pressure while also acting as a direct feedback mechanism.

- The technician can use the gauge to optimize seal pressure and deflection around the door frame

- Also used to assess before and after adjustments to an assembly process or technique

|

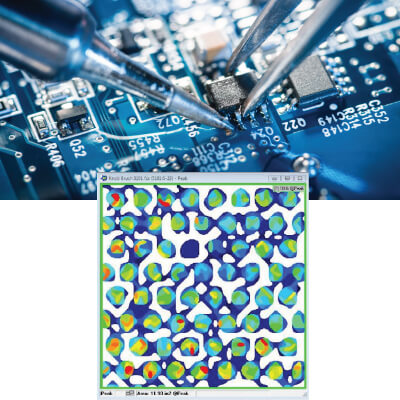

Electronic Assembly: Pick and Place

|

Challenge:

To obtain clear, verifiable data on how a robotic manufacturing system performs very specific movements.

- Capture changes in pressure alignment in the production process

- Reduce risks that could cause defects and affect yield

Solution:

An I-Scan system used as part of the operation's machine setup procedure was used to verify all robotic elements were interfacing properly.

- Confirms that the correct amount of force is applied in every movement

- Laid the framework for an advanced pick and place machine integrated with pressure mapping capabilities

|

Not seeing your specific application?

Explore More Application Stories

There have been a number of research projects conducted where Tekscan's pressure measurement technology has played a crucial role. To view the list of these research studies, download the bibliography for Pressure Mapping Applications.

Related Products