Temperature Mapping

Measure temperature between two surfaces, utilizing a thin and flexible sensor. The resulting data and our analysis tools offer insights to enhance product design, manufacturing, quality, and research.

Have questions? Contact Us

Measure temperature between two surfaces, utilizing a thin and flexible sensor. The resulting data and our analysis tools offer insights to enhance product design, manufacturing, quality, and research.

Tekscan has enhanced the I-Scan™ platform with a new thin-film temperature mapping capability, enabling you to capture detailed temperature distribution across a surface—or in between two surfaces where thermal cameras can’t.

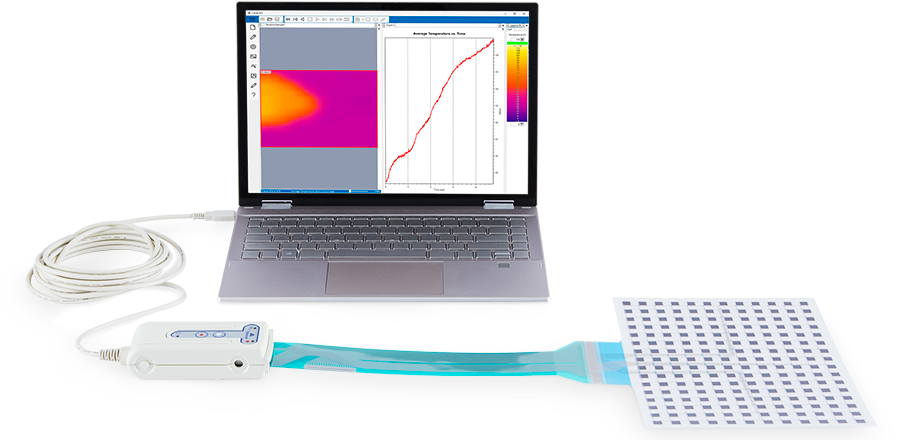

This innovative solution integrates I-Scan software and electronics with a thin-film temperature sensor to deliver precise, high-resolution thermal analysis in an easy-to-use format. The trimmable sensor can be used on its own or, depending on your selected package, paired with a Tekscan pressure mapping sensor—allowing you to collect thermal and/or pressure data for deeper insights into product performance and process optimization.

Measure Where Thermal Cameras Can’t

Not Sensitive to Emissivity

Visualize Thermal Propagation

|

Comprehensive Data Insights

Streamline Data Collection

Correlate Pressure & Temperature

Seamless Integration with I-Scan

|

Sensors

|

Electronics

|

Software

|

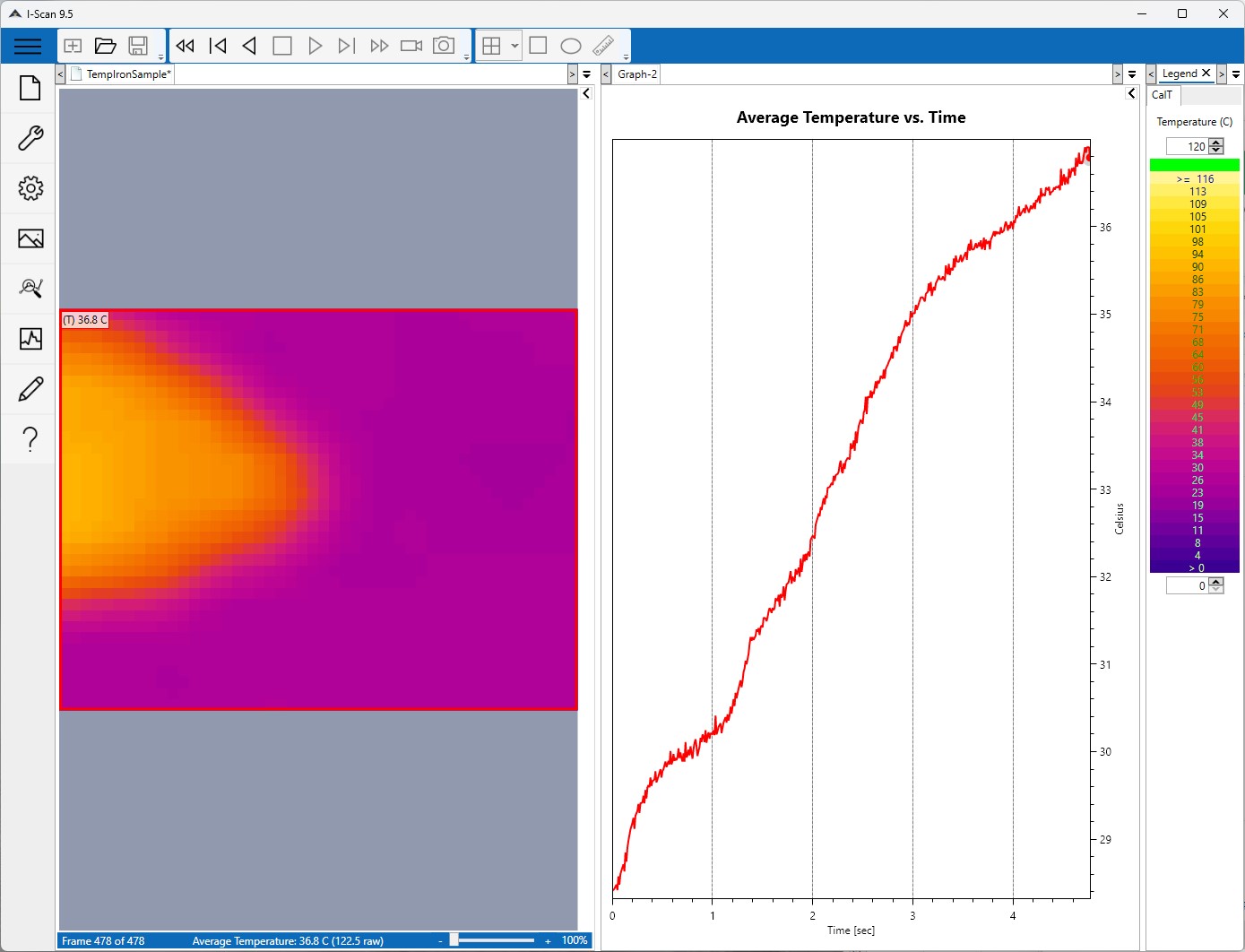

Temperature Sensor Software over Time Graph

Temperature Sensor Software over Time Graph

I-Scan software enabled for Temperature Mapping provides real-time temperature mapping and visualization for deeper analysis. Built on Tekscan’s I-Scan 9.5 platform, it offers customizable heatmaps, streamlined calibration, and intuitive tools for efficient and accurate data analysis.

|

|

|

Packaging and Manufacturing

|

Electronics & Semiconductor

|

|

|

This thin, flexible, and trimmable sensor provides direct surface contact for accurate, high-resolution temperature mapping with 192 sensing points across a 0-120°C range.

Want to know how our pressure mapping sensors are made, and how they work? This short video provides a visual overview of Tekscan's pressure mapping sensor technology.

Learn the pros and cons of using pressure indicating film versus tactile pressure sensors.