Have questions? Contact Us

Obtain a uniform nip impression for roll setup, maintenance, consistency, and longevity

|

Taking routine nip impressions can help identify:

|

|

Nip Pressure Measurement Options

There is no "one-product-fits-all" approach but depending on your application needs Tekscan offers three solutions:

Comparison of Nip Impression Systems

FujiFilm Prescale ("Nip Impression Paper" / "Fuji Impression")

Nip impression paper is used to measure contact pressures and is as easy as passing the film through the nip rollers. The film structure consists of micro-encapsulated color forming and developing material. When pressure is applied to the film, a red color impression is formed in varying density according to the amount of pressure and pressure distribution.

|

Main features

|

Example pressure profile from nip impression paper Example pressure profile from nip impression paper |

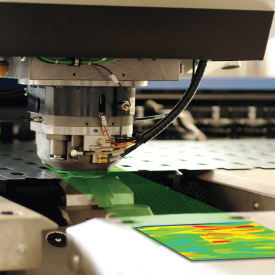

I-Scan™

I-Scan is a versatile solution for optimizing a process or manufacturing parameters. The I-Scan nip impression sensor is placed in the nip for real-time roller pressure measurement. With a wide range of sensor form factors and data analysis tools in the software, I-Scan is a powerful tool for a research and development team to improve yield.

|

Main features

|

Data returned from a square I-Scan sensor Data returned from a square I-Scan sensor |

Nip Pressure Alignment Tool™ (NPAT)

NPAT is an advanced, easy-to-use tool used to capture nip footprints and relative pressure distribution between nip rollers. The system utilizes a sensor made up of an array of thin and flexible pressure sensitive bands, which can be configured to match the size of an application.

|

Main features

|

Sample software output from Tekscan's NPAT Sample software output from Tekscan's NPAT |

Compare Solutions with this Chart

| Nip Impression Paper | I-Scan | NPAT | |

| Primary Use | Maintenance tool | Instrumentation setup. Used by R&D engineers to optimize processes. | Maintenance & setup tool |

| Data Captured | Static display of pressure that captures peak load only; No timing data | Real-time, dynamic display of contact area of the nip | Relative nip uniformity and pressure distribution |

| Ideal Nip Roll Size | Cut to size | > 450 mm (18 in) | 450 mm (18 in) to 10,973 mm (432 in) |

| Analysis Capabilities | Digital scanner; software only displays degree of pressure | Featured packed, robust software with in-depth analysis tools and features | Robust software with analysis tools and features |

| Efficiency & Productivity | Single-use product with a cumbersome setup process | Reusable, mix and match sensors capturing in-depth analysis of nip contact area | Reusable sensors that capture changes in pressure distribution in real-time |

Not Sure Which Solution is Right for You?

Related resources

Ensure & Verify Nip Roll Uniformity

Proper pressure distribution between rolls allows for an efficient manufacturing process and the production of a uniform product. How can pressure mapping help?

Keep Your Production Rolling with the Nip Pressure Alignment Tool

Watch this 2 minute video to view the true value of the Nip Pressure Alignment Tool.

Embed Confidence into Your Machine

How can integrating pressure mapping technology into your machine design help you create the ultimate user-friendly machine? This free eBook explains!

I-Scan VS Pressure Indicating Film - How Do they Compare

I-Scan and Pressure Indicating Film are two technologies commonly used to verify nip uniformity. Which one is right for your operation?