Whether you’re designing batteries for electric vehicles, industrial systems, or consumer electronics, your goals remain the same: maximize performance, extend lifespan, and ensure safety.

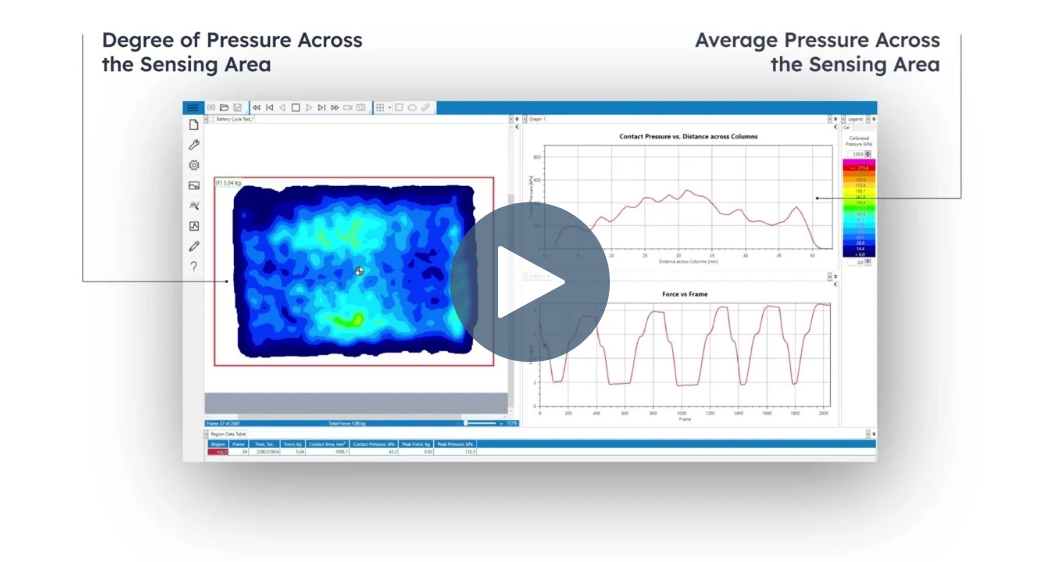

Achieving those goals requires understanding how pressure and temperature behave throughout the battery lifecycle—from early design to full-scale production. Tekscan’s I-Scan pressure mapping system, also available with temperature sensing capabilities, gives engineers real-time, high-resolution data to improve battery reliability, performance, and manufacturability.

Why Monitor Pressure & Temperature in Battery Systems?

Pressure and Temperature Mapping in real-time.

Pressure and Temperature Mapping in real-time.

During charge and discharge, internal battery components expand and contract due to thermal and electrochemical changes. This cycling can lead to:

- Mechanical delamination

- Gas formation

- Deformed surfaces

- Capacity fade

- Thermal runaway

Localized pressure and temperature variations—if undetected and not accounted for in the battery fixture design—can compromise performance, shorten lifespan, or lead to failure. Real-time pressure mapping allows engineers to:

- Maintain uniform stack pressure

- Reduce variability during formation

- Identify defects early

- Improve safety and durability

Measuring Battery Pressure in Real Time

I-Scan provide a dynamic view of surface pressure across battery housings, fixtures, and internal components. Unlike pressure-sensitive film, the system delivers repeatable, actionable data in real time.

- Identify high and low pressure zones

- Monitor pressure uniformity

- Track changes over time

- Capture pressure behavior during thermal events

EV Battery Applications for Pressure Mapping

Tekscan solutions support pressure and temperature sensing throughout the development and production of lithium-ion batteries across form factors and industries.

Prismatic Cells

Pressure mapping applications for EV Batteries.

Pressure mapping applications for EV Batteries.

- Monitor swelling to extend cycle life

- Optimize pressure during formation

Module

- Validate consistent stack pressure

- Identify anomalies in assembly

Pack

- Detect pressure and temperature hot spots

- Feed sensor data into battery management system for smart safety control

Lifecycle Testing

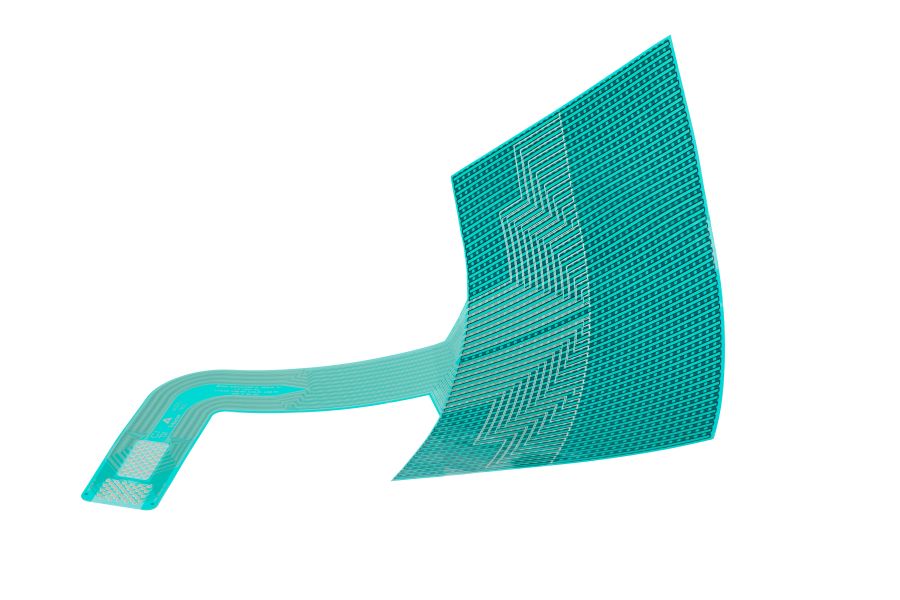

Flexible Tekscan Model 7800 matrix sensor wraps around battery components.

Flexible Tekscan Model 7800 matrix sensor wraps around battery components.

The Model 7800 is designed specifically for battery testing. This flexible, thin sensor wraps around the cell and between layers to provide a 360◦ view of battery pressure. The long 90° tab keeps electronics safely outside the housing. It enables long-term, high-resolution data collection across full lifecycle testing protocols.

The sensor supports applications including:

- Multi-month charge/discharge testing

- Correlating pressure and temperature with capacity and impedance

- Detecting deformation, gas formation, and delamination

- Comparing new chemistries or structural designs

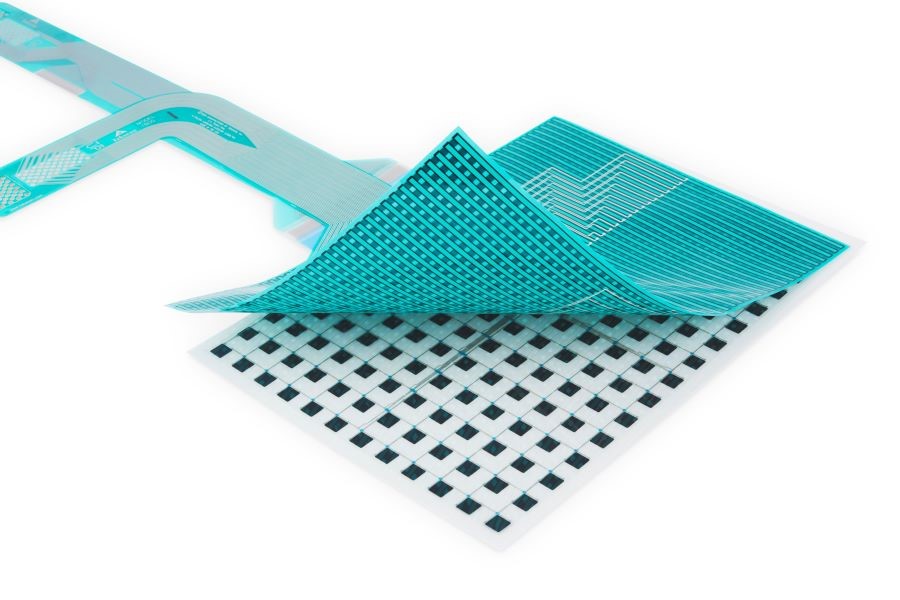

Flexible Tekscan Model 7800 and T800 matrix pressure and temperature sensors.

Flexible Tekscan Model 7800 and T800 matrix pressure and temperature sensors.

For comprehensive insights, combine pressure and temperature mapping during stress testing. The 7800 pressure sensor and T800 temperature sensor are designed to work together for simultaneous correlated temperature and pressure data.

Supporting the Future of Battery Design

Whether you’re working with lithium-ion, silicon anode, or solid-state chemistries, Tekscan gives you the tools to validate, refine, and scale with confidence. Use pressure and temperature mapping to:

- Detect swelling and thermal buildup during charging

- Define the optimal stack pressure window

- Prevent failure modes early

- Validate new housing or cell designs

- Improve formation and QA protocols at scale

Ready to bring advanced sensing into your battery development or production process?

We can help you find or customize a product for your application.