Pressure Welding or Resistance Welding for Medical Devices

Challenge

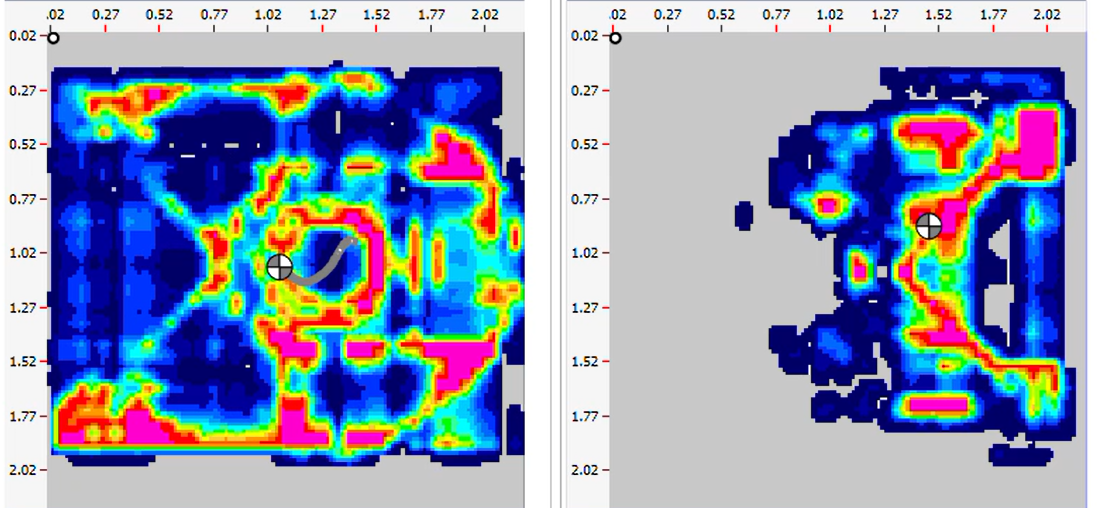

A manufacturing assembles their device with a pressure weld and wanted to validate the pressure and load. They had tried using prescale film but didn't get the data them wanted.

Solution

After testing the I-Scan system with a 5051 sensor, the customer was able to see the true pressure data exerted in their manufacturing process that they had not seen before with just prescale pressure sensitive film. This allowed them to refine and calibrate the system, resulting in more reliable production.

Why Pressure Measurement is Critical in Ultrasonic Welding

Proper Energy Transfer

- Pressure ensures good contact between the parts and the welding horn (sonotrode).

- Too little pressure = poor energy transfer → weak or incomplete weld.

- Too much pressure = part deformation, energy loss, or surface damage.

Weld Quality and Strength

- The correct pressure balances with vibration amplitude and time to form a strong weld without damaging the material.

- Precise pressure prevents issues like flash, voids, or internal cracks that compromise the device’s strength or function.

Repeatability and Process Control

- Medical manufacturing demands tight tolerances and consistent weld quality.

- Controlled pressure ensures reliable welds across batches, crucial for regulatory compliance (FDA, ISO 13485).

Avoiding Overweld or Cold Weld

- Overweld (excess pressure + time) can cause part collapse or damage.

- Cold weld (too little pressure or time) results in a weak joint.

- Pressure must be measured and tuned for material type, part geometry, and weld design.

Real-World Example: Ultrasonic Welding in Catheter Manufacturing

In making catheters, soft plastic tubing is welded to hubs or connectors. If pressure is off:

- Too high: tubing deforms or collapses, blocking fluid pathways.

- Too low: tubing won’t bond well, leading to leaks or detachment during use.

Controlled pressure, combined with optimal amplitude and time, ensures smooth, clean, leak-proof joints — essential for patient safety and device performance.

Pressure Measurement in Medical Device Welding

In medical device manufacturing, precise pressure measurement is critical for achieving high-quality welds, especially in resistance welding, a common method used to join small components like fine wires, foils, or terminals.

Resistance welding is widely used in assembling components such as:

- Pacemaker leads

- Catheter guide wires

- Sensor connections

- Microelectronic terminals

The I-Scan™ pressure mapping sensors can be placed on either side of an assembly mechanism. to ensure that your device is being assembled consistently according to your specifications.

Tekscan’s patented, thin-film sensors are available in different pressure ranges, are reusable, and provide accurate pressure readings. With the help of our highly qualified sales and engineering support team, each system is configured to meet your specific needs.