Setting Nip Pressure for RFID/Smart Label Manufacturing Using Pressure Measurement

A major RFID manufacturer recently contacted us for help with their manufacturing consistency. RFID (Radio Frequency Identification) and smart labels enhance efficiency, accuracy, and convenience in a variety of industries. They track products in shipping, inventory and supply chain management. They are used for authentication of high value goods and are a valuable efficiency for automated scanning without requiring line of site or manual intervention.

Challenge

Nip pressure, uniformity, and setup are critical factors in the RFID manufacturing process. A misaligned roll can lead to poor print quality, inconsistency, and considerable product defects, increasing costs and product waste. The RFID must be manufactured at a consistent pressure between the adhesive and substrate layers.

Solution

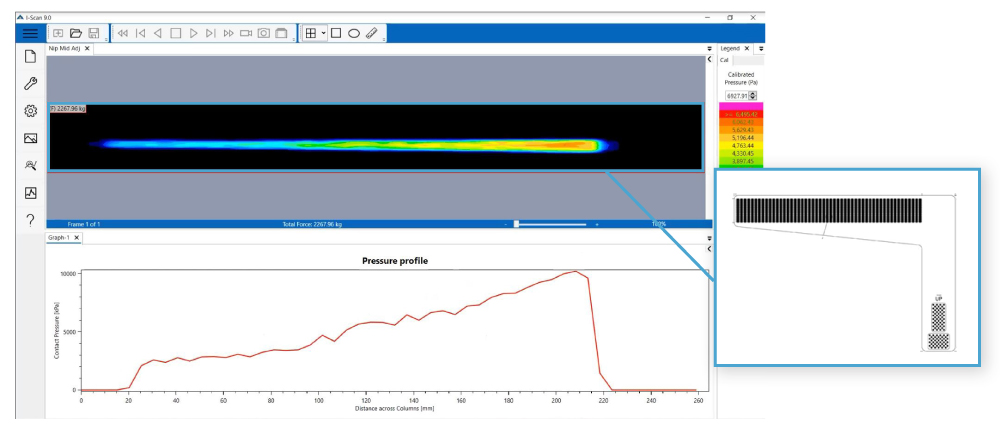

The I-Scan system is a key diagnostic and machine set-up tool for balancing nip rolls. It is used to capture nip footprints and relative pressure distribution between nip rolls. The system's minimally intrusive sensors can be positioned adjust blade height, pressure and tightness, ensuring the desired pressure distribution along the length of the blade is achieved.

Tekscan's pressure mapping systems allow for real time viewing of the pressure and can capture and display the pressure pattern during the manufacturing or printing. With the help of Tekscan's highly qualified sales and engineering support team, each system may be configured to meet your specific needs.

Sensor Map printing.

Sensor Map printing.

Benefits of Pressure Mapping

- Faster machine set-up

- Increased product yields

- Improved product quality

- Improved print consistency

See how Pressure Mapping Technology can help streamline calibration and machine setup processes: